Zert RM – Riskhantering

Samla all riskhantering på ett ställe

Zert RM är ett webbaserat program som samlar din riskhantering på ett och samma ställe.

Programmet gör det enkelt att såväl identifiera som värdera och kommunicera riskerna i din organisation, eftersom Zert RM är uppbyggt av moduler anpassar du det dessutom enkelt efter dina behov.

Ta kontroll över dina risker

Anpassas utifrån ditt behov

Ger kontroll över allt

Är alltid tillgängligt

Riskhantering handlar i grund och botten om att förutse sådant som kan gå fel och se till att sådant som redan har gått fel inte händer igen. I Zert RM hanterar du allt från inrapportering av händelser till avancerade tekniska riskanalyser. Därefter kan du enkelt bedöma riskerna utifrån samma värderingsgrund och kommunicera dem till alla som du vill ska ta del av dem.

Synliggör riskerna

Zert RM gör det enkelt att snabbt överblicka risker. I samma stund som riskanalysen är färdig ser du resultatet i grafiken.

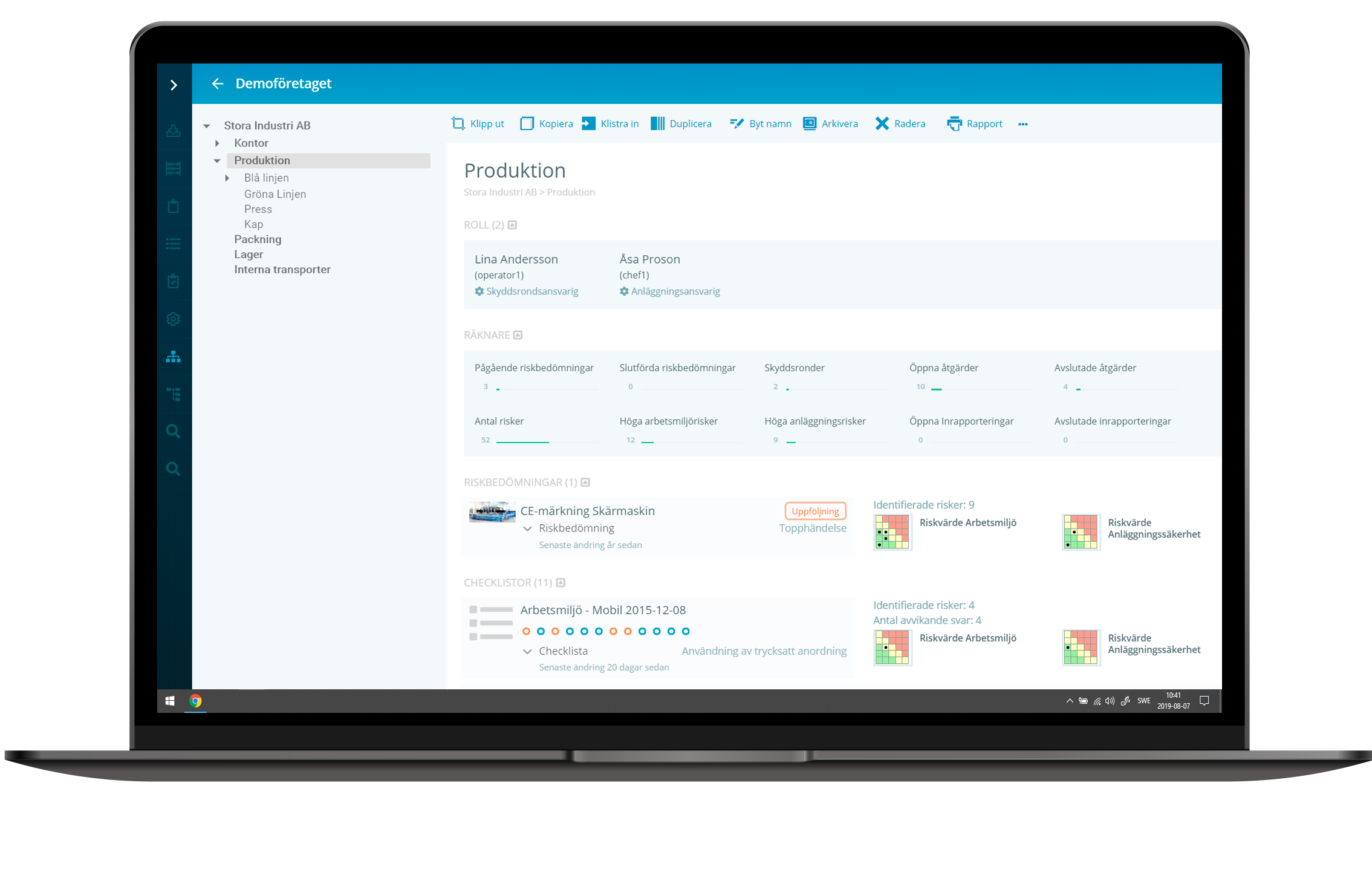

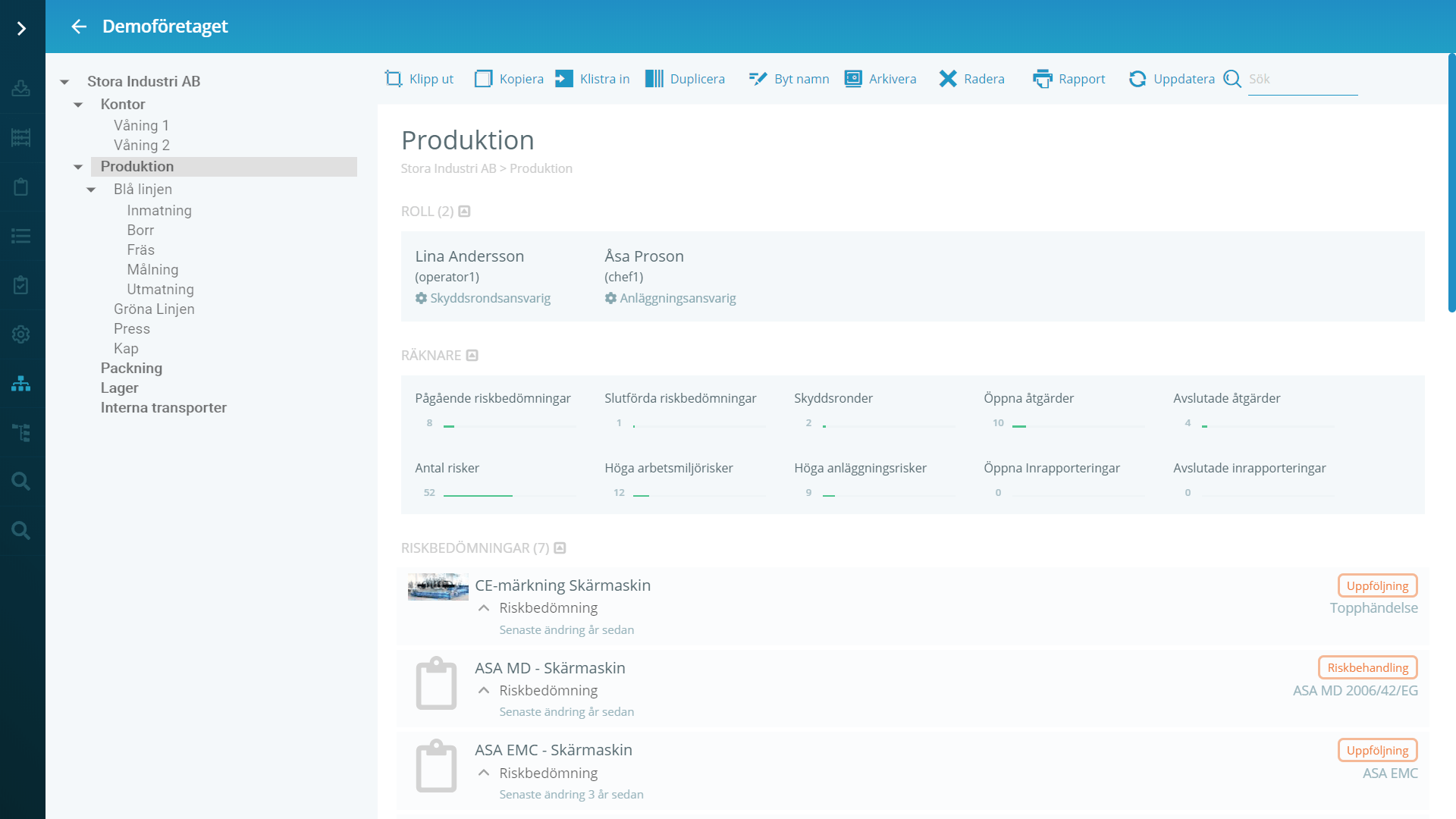

Struktur

I Zert RM kan du bygga upp en eller flera strukturer över din anläggning likt en trädstruktur. Strukturerna kan vara uppbyggda enligt exempelvis företagets anläggnings- eller organisationsstruktur.

Strukturen används som en översikt där du kan se vad som har genomförts på respektive avdelning, maskinlinje, processavsnitt, maskin eller trycksatt anordning.

Genom strukturen kan chefer se vad som genomförs på sin avdelning på ett enkelt sätt och kan få statistik för varje sektion.

Exempelvis på statistik som kan användas i systemet:

Antalet pågående / slutförda åtgärder

Antalet försenade åtgärder

Antalet pågående / slutförda Riskbedömningar

Antalet genomförda checklistor

Antalet skyddsronder

Antalet höga arbetsmiljörisker, miljörisker, anläggnings risker.

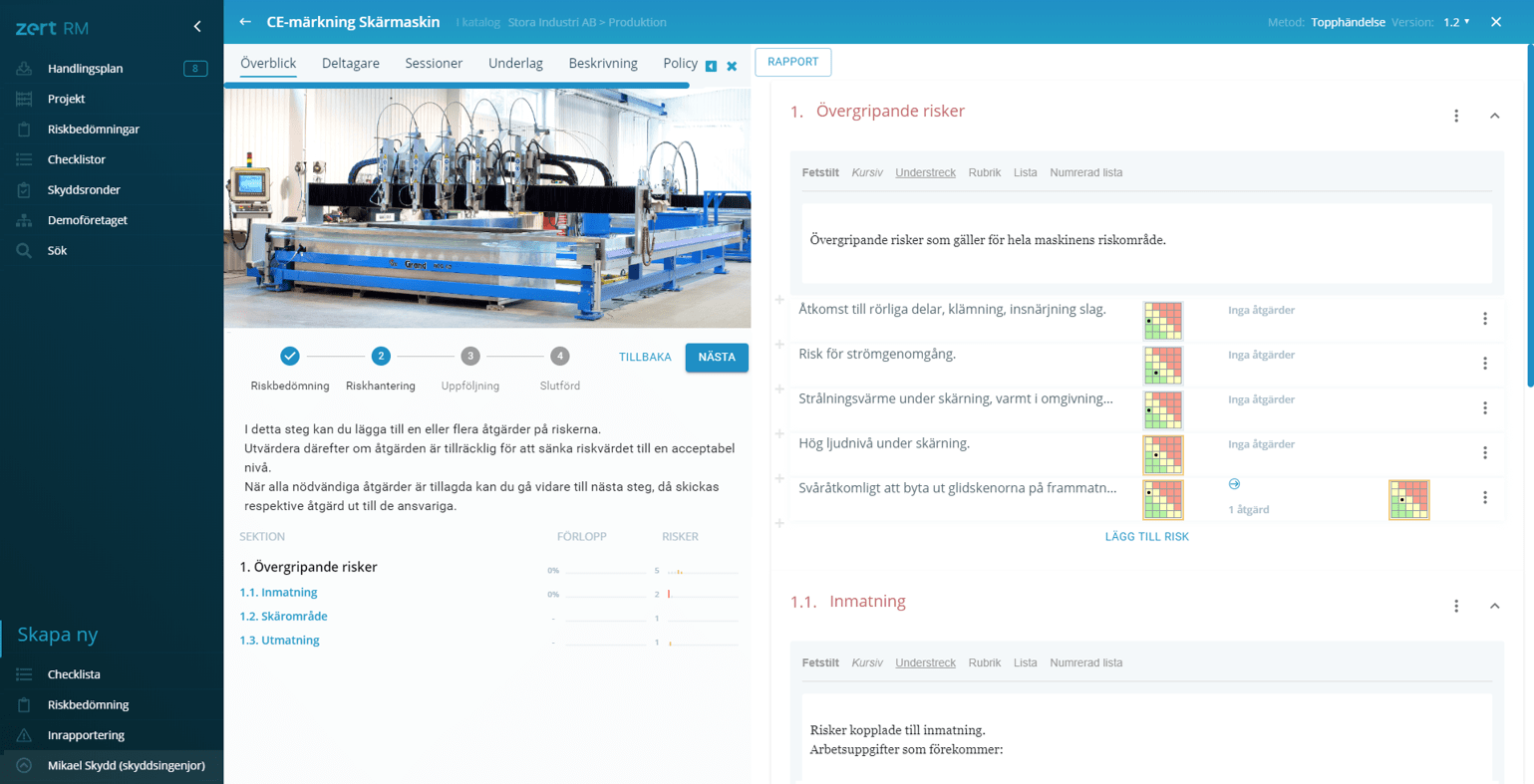

Riskbedömning

I Zert RM hanterar du alla typer av riskbedömningar, allt från enklare riskbedömningar till avancerade maskin- och processriskbedömningar.

Alla Riskbedömningsmetoder är baserade på lagkrav och kundernas behov så att rätt typ av riskbedömning används vid rätt tillfälle. Det finns även möjlighet att ställa upp riskmatriser efter behov.

I systemet finns färdiga metoder för att uppfylla kraven för exempelvis:

CE-märkning enligt Maskindirektivet 2006/42/EG (ISO 12100:2010)

Användning av arbetsutrustning AFS 2006:4

CE-märkning enligt PED direketivet 2014/68/EU (AFS 2016:1)

Processriskbedömningar HAZOP

Kontroll och användning av tryckbärande anordning AFS 2017:3

Det går också att lägga in sina befintliga riskbedömningsmetoder så att man inte behöver byta arbetssätt bara för att man börjar använda ett system.

I en riskbedömning kan man välja att samtidigt bedöma risker med arbetsmiljö, yttre miljö, anläggningsrisker, ekonomi och produktionsrisker etc.

Så går en riskbedömning till

I Zert RM genomförs riskbedömningar i fyra steg, i enlighet med ISO 31 000.

Steg 1: identifiera och analysera riskerna

Steg 2: Lägg till åtgärder på risker som kräver ytterligare riskreduktion

Steg 3: Tilldela åtgärder till en ansvarig person

Steg 4: Färdigställ och avsluta riskbedömningen

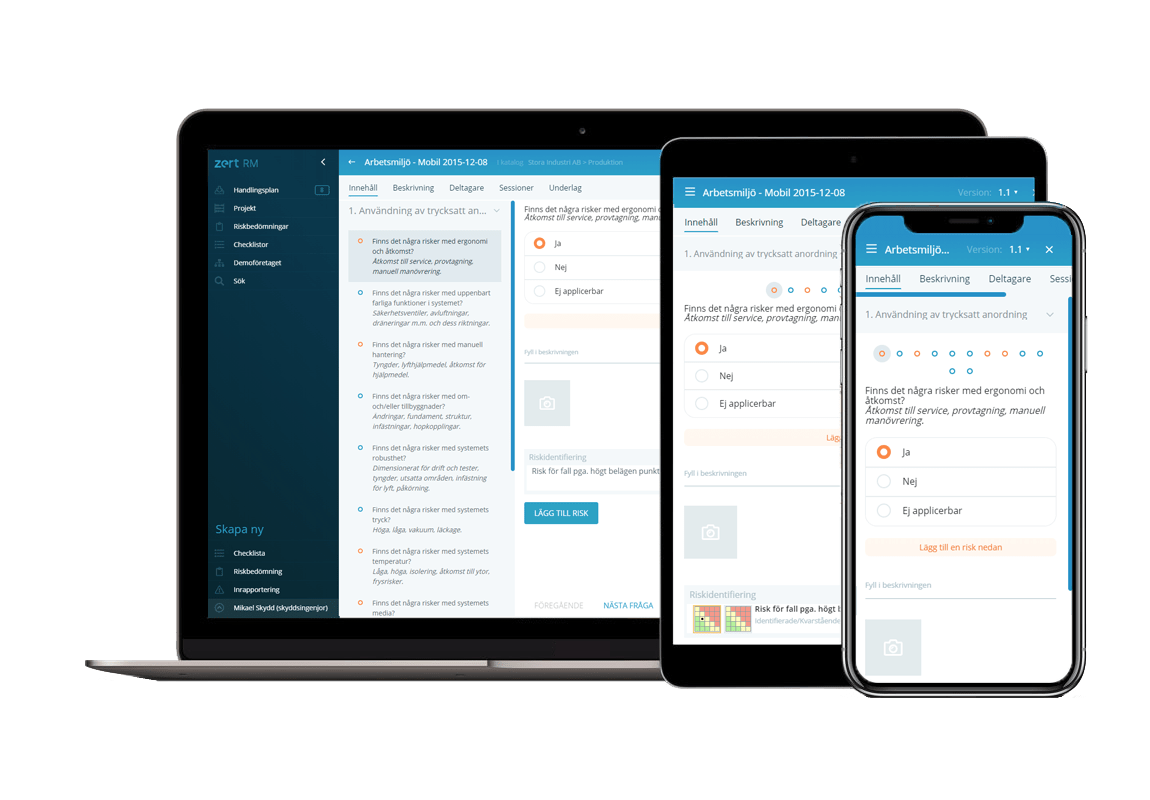

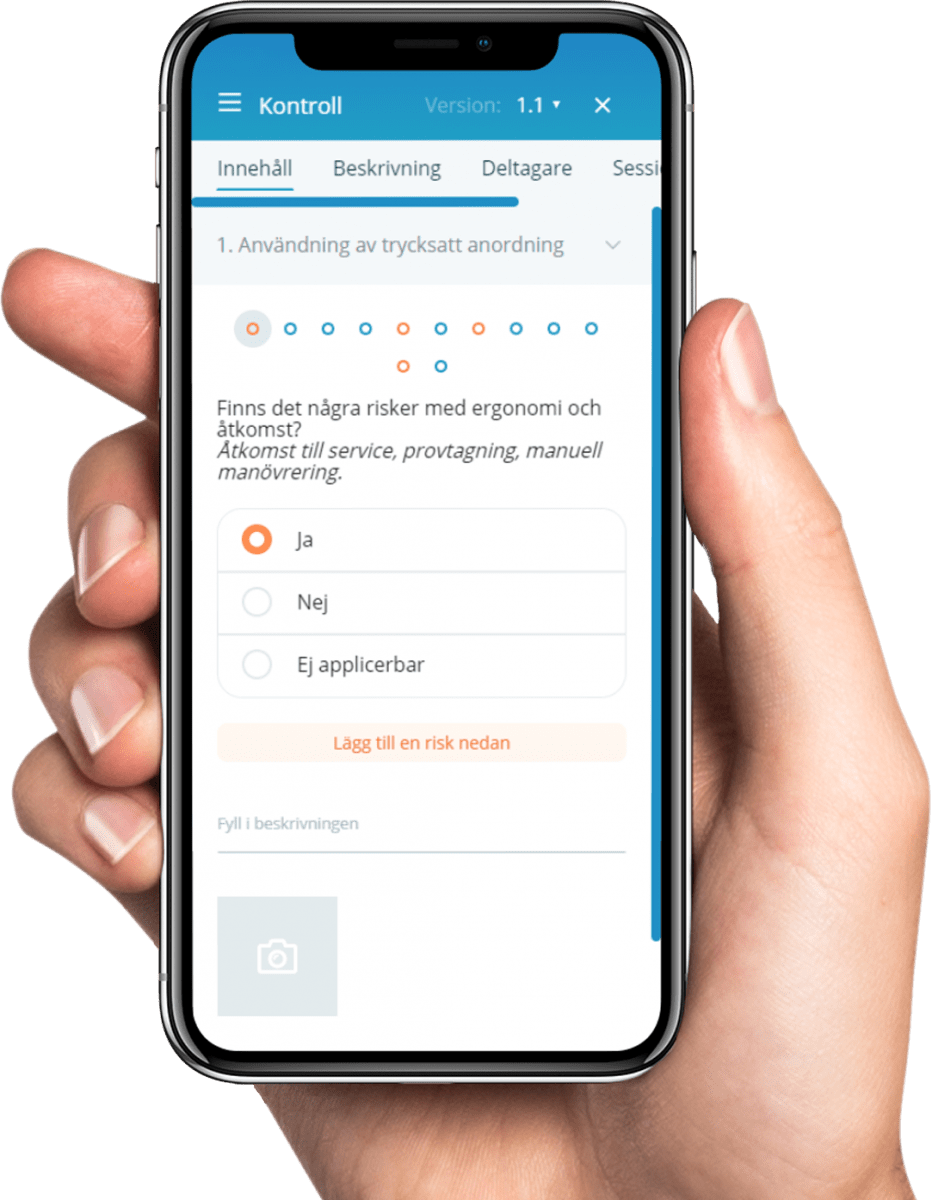

Checklistor

Checklistor i Zert RM är ett kraftfullt verktyg, det kan det användas för att göra enklare riskbedömningar där man med hjälp av frågornas utformning styr in den som gör riskbedömningen i rätt tankesätt. I checklistor har man samma möjligheter att skapa risker, göra riskvärderingar och sätta upp åtgärder som man har i en Riskbedömning.

Det går också att använda checklistor för att få stöd i att man gjort rätt inför ett kommande arbete, men även för att säkerställa att man uppfyllt alla krav.

Exempel på användningsområden kan vara:

Uppfylla kraven i Maskindirektivets Bilaga I inför CE-märkning

Fortlöpande tillsyn och riskbedömning enligt AFS 2017:3

Riskbedömning före Underhållsarbete

Säker avställning

Vi på Zert erbjuder hjälp med att ställa upp checklistor utifrån kundens behov som uppfyller gällande lagkrav.

Checklistorna och Ronderna går att utföra på plats, via mobilen eller surfplatta för smidig användning.

I Zert RM går det enkelt att administrera och skapa nya checklistor när behovet ändras för användaren. Fullständig versionshantering ger en möjlighet att blicka tillbaka på vad som genomförts och hålla koll på nuvarande versioner.

Ronder

Checklistorna går även att göra periodiserade och kallas då för Ronder. Då går det automatiskt ut påminnelser när det börjar vara dags att genomföra checklistan.

Exempel på ronder kan vara:

Återkommande kontroll av säkerhetsfunktioner på en maskin

Periodiska skyddsronder

Vi på Zert erbjuder hjälp med att ställa upp checklistor utifrån kundens behov som uppfyller gällande lagkrav.

Checklistorna och Ronderna går att utföra på plats, via mobilen eller surfplatta för smidig användning.

I Zert RM går det enkelt att administrera och skapa nya checklistor när behovet ändras för användaren. Fullständig versionshantering ger en möjlighet att blicka tillbaka på vad som genomförts och hålla koll på nuvarande versioner.

Få översikt över handlingsplanen

Zert RM håller koll på allt åt dig. Programmet påminner dig om när något ska vara klart, delegerar automatiskt uppgifter till dina medarbetare och sammanställer allt med ett enda knapptryck.

Överblick

Handlingsplanen ger dig överblick och du får automatiska påminnelser.

Sammanfattning

Listan visar en sammanfattning av aktiviteterna i handlingsplanen.

Status

Aktivitetsbeskrivningen visar status på aktiviteten och övrig information.

Kundberättelser

Så här använder våra kunder våra program och tjänster:

Upptäck fördelarna med Zert RM

Samla allt som rör risk och säkerhet och låt till exempel underleverantörer och externa projektledare bidra med sina delar. Analysera allt från produkter och anläggningar till direkta projektrisker.

Ett naturligt led i all riskhantering är det systematiska förbättringsarbetet och ledningssystemet. Därför stöder RM dokumentation och kommunikation genom hela PDCA-cykeln (Plan, Do, Check, Act).

RM samlar alla steg i din arbetsprocess i ett och samma program. Allt du behöver för att kunna arbeta effektivt finns där från början.

RM fungerar i både Android och iOS. I stället för att skriva ut checklistan kan du fylla i den direkt från mobilen, pekplattan eller datorn och spara både tid och papper.

När du arbetar med till exempel en checklista kan du göra riskvärderingen direkt i samma elektroniska dokument. Åtgärder kopplas automatiskt till varje enskild kryssfråga och när åtgärderna sedan delegeras ser mottagaren ursprungskällan och eventuella andra åtgärder som ska genomföras i samma område.